☰

Malletech’s roots in technology

Since 1982, Malletech has been the world’s premier manufacturer of the highest-quality keyboard percussion mallets. We have a vast selection of one-tone, two-tone and multi-tone/extended-response models and a unique model ID system to help you understand what they will sound like before you buy. When you compare them with ordinary mallets, you will feel and hear why most of the greatest keyboard percussionists in the world play with Malletech.

Complex Response Characteristics

Unlike the great majority of mallets sold today, our “multi-toned” models are designed to respond to the velocity of the stroke by changing timbre as well as dynamics. This can assist the soloist by boosting brightness and “cutting power” — but only when needed: mellow at low levels, aggressive at higher dynamics. Complex performance characteristics require complex construction techniques, such as tension adjustments during the winding process, multiple under-layers of contrasting materials and multiple layers of wrapping — all with different angles and tensions. Malletech has the design expertise and computer-controlled winding technology to control all those parameters.

Two-Toned and Multi-Toned Models

Our “multi-toned” models are designed to smoothly change their tone color as the volume increases. A multi-toned mallet designated as “soft to hard” will sound soft and mellow at low dynamic levels, gradually changing to hard and bright at high volume. The “two-toned” (or ‘Z’) models designated as “very soft and very hard” will sound very soft and mellow at low and medium levels, but will abruptly change to very hard and bright at high volume levels. A “single-toned” mallet, like most traditional mallets, is designed to maintain its basic sound characteristics at all volume levels.

Threaded Mallet Heads & Handles

Almost every Malletech marimba, xylophone, and bell model has screw threads tapped in to the hole in the head and corresponding threads tapped onto the birch or rattan handle to create the strongest “glued and screwed” connection possible. This extra manufacturing step doubles the area of contact between the glue and the ball and produces a much more reliable mechanical bond between the stick and head than traditional “glue only” methods.

Custom-Made Yarns

You won’t find Malletech yarns at your local knitting store. That’s because each of our yarns has been custom-designed for a specific sound quality or performance parameter, and then “spun” or “drawn” specifically for us. Some yarns are designed for minimal contact noise and smoothest rolling, and others for articulation, projection or maximum resistance to wear. Malletech was the first mallet company in the world to use synthetic “poly” yarns. Not a single pair of Concerto Series mallets has ever been returned because of fraying, and some made in the 1980s are still making music today.

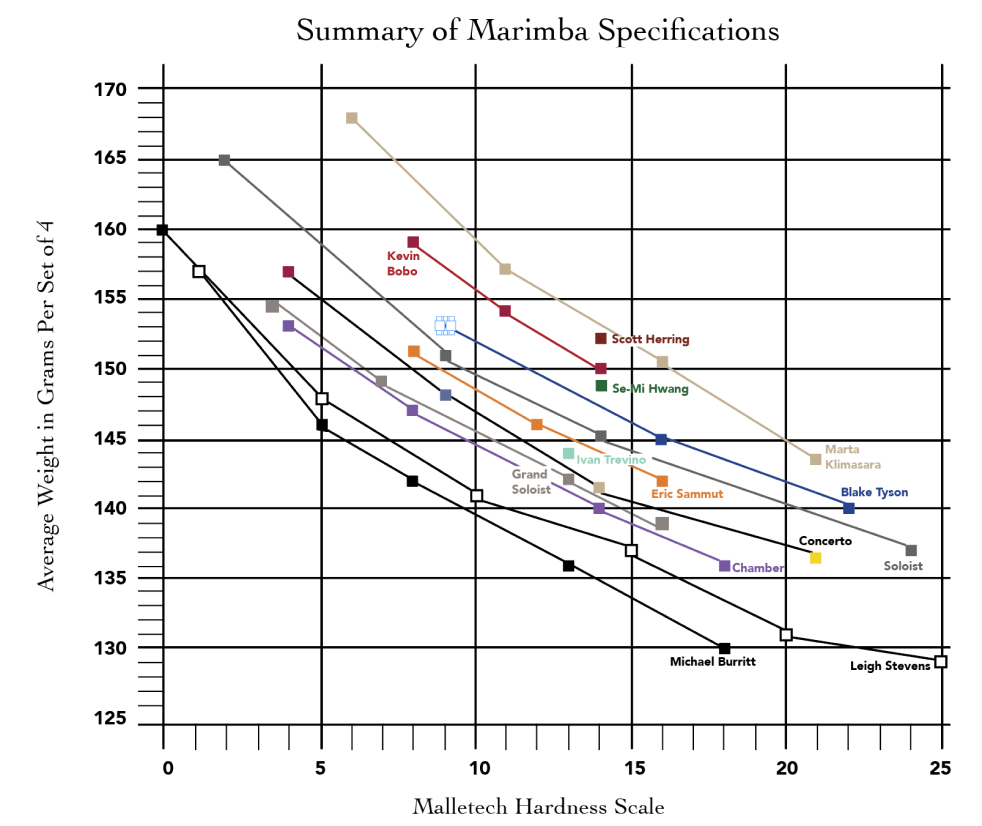

Malletech® Exclusive Model Numbering System

To aid in the selection of mallets, every Malletech model is assigned a number that reflects its brightness of tone (apparent hardness) at maximum volume. The scale of model numbers ranges from 0 (extremely soft) to 50 (extremely hard). Thus, at fff, the LS17Z sounds slightly brigher than the LS15. A difference of only one or two numbers on the scale may not be audible. For example, a DS11 has about the same brightness of tone at maximum volume as a JC12, even though these two models are very different in weight and winding procedure. Two models may sound almost identical at maximum volume (similar number), yet may have very different apparent hardness, response and rolling characteristics at low-volume levels. Our model numbering system doesn’t tell you everything about a mallet, but like our other features, it’s a mallet-length ahead of the competition.